Product Description

Product Introduction

Product Type

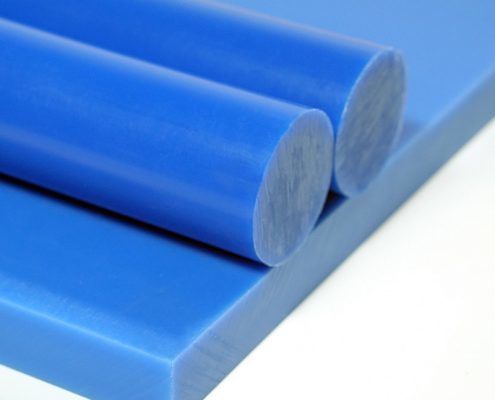

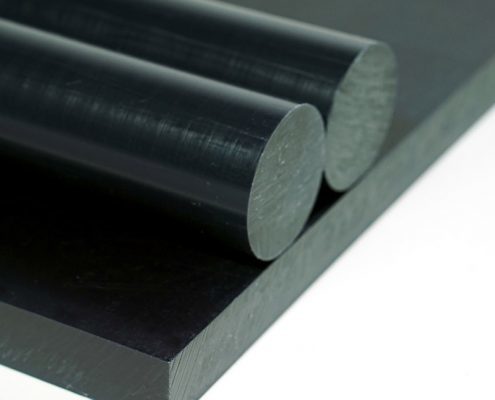

2. MC Nylon MOS2

A product with improved surface strength, abrasion resistance and abrasion resistance by adding Mos2

3. MC Nylon OIL

A product with reduced friction coefficient and improved abrasion resistance by adding oil lubricant

4. MC Nylon LUB

A product with improved heat resistance and abrasion resistance by adding solid lubricant (Lube)

5. MC Nylon ESD

A product with significantly reduced electrical resistance by adding carbon for antistatic (ESD) function

6. MC Nylon E

A product that combine the features and economics of MC nylon with extruded products

Product Use

- Electronic equipment

- Conveying machines

- Energy industry

- Industrial parts

Company Profile

Ilwoong Platech

Since our founding in 1988, we have been devoted to professional quality control, localization of imported products, technology development and facility investment with the aim of supplying the best quality engineering plastic products to our customers at the best price. As a result, we have been recognized for quality and technology in various types of engineering plastic such as PTFE business, extrusion & UHMW-PE business, MC Nylon business, PVC business, finished product processing business.

We are a company that produces materials with recognized quality from engineering plastic distribution in Korea. We have grown to become a company that localizes the imported products, and exports to other countries around the world. Ilwoong Platech Engineering Plastic is growing into a world-class engineering plastic company through steady growth of existing businesses and efforts to pursue new values.

Superior Mechanical Properties

MC Nylon rods deliver exceptional strength and resilience. With a high modulus of elasticity and compressive strength, they are ideal for use in heavy-duty mechanical systems. Their balance of hardness and elongation at break allows both durability and flexibility, reducing the risk of component failure and extending service life.

Versatile Industrial Applications

Suitable for a wide temperature range, MC Nylon rods excel in multiple industries, including machinery, automotive, and engineering. Their green color aids identification on production floors, and the excellent machinability ensures easy customization for specific requirements. The rods are distributed, exported, and supplied worldwide from Korea South, ensuring consistent availability.

Low Maintenance, High Performance

With low water absorption and a moderate friction coefficient, MC Nylon requires minimal maintenance and performs reliably even under challenging conditions. Its chemical resistance and robust mechanical properties make it a preferred choice for applications involving separation, insulation, and load distribution.

FAQ's of MC NYLON:

Q: How can MC Nylon rods be processed or machined for custom applications?

A: MC Nylon rods offer excellent machinability, allowing operations such as turning, drilling, milling, and cutting with standard metalworking tools. This facilitates precise shaping and customization for various industrial parts and components, while maintaining their high mechanical integrity.Q: What benefits does using MC Nylon provide in industrial applications?

A: MC Nylon is valued for its high tensile and compressive strength, low water absorption, and wide operating temperature range. These attributes ensure reliable performance, reduced maintenance, and extended service life for components in demanding industrial environments.Q: Where can MC Nylon rods be used effectively?

A: MC Nylon rods are well-suited for use in mechanical, automotive, and engineering systems, including gears, bearings, insulators, seals, and load-bearing parts. Their durability supports applications needing strength, flexibility, and precision.Q: When is MC Nylon preferred over other engineering plastics?

A: MC Nylon is often chosen when high mechanical strength, excellent machinability, and resistance to wear are required. Its ability to function in temperatures from -40C to +100C and low water absorption make it suitable for environments where dimensional stability is important.Q: What is the process of sourcing MC Nylon rods from Korea South?

A: As a manufacturer, supplier, exporter, and trader, sourcing MC Nylon rods involves contacting authorized distributors or exporters based in Korea South. Orders are fulfilled according to required specifications and logistical arrangements for local or international delivery.Q: How does the material's modulus of elasticity benefit its usage?

A: With a modulus of elasticity of 3200 MPa, MC Nylon maintains structural integrity under load, distributing stress evenly and minimizing deformation. This property is advantageous in applications where maintaining precise shapes and dimensions is critical to performance.Q: What is the significance of MC Nylon's friction coefficient in its applications?

A: A friction coefficient of 0.30 indicates moderate resistance to sliding, which helps reduce wear and noise in moving parts. This makes MC Nylon particularly beneficial for components such as bushings and gears operating with frequent movement.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese