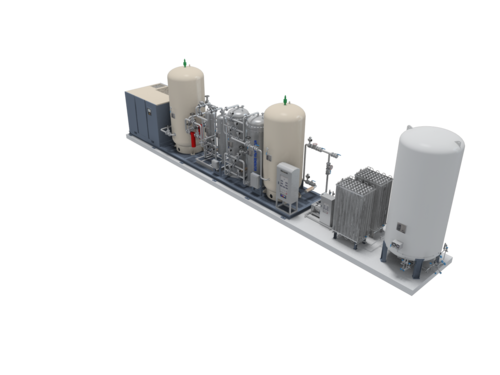

N2 PSA - Membrane Package

Product Details:

N2 PSA - Membrane Package Price And Quantity

- 1 Unit

Product Description

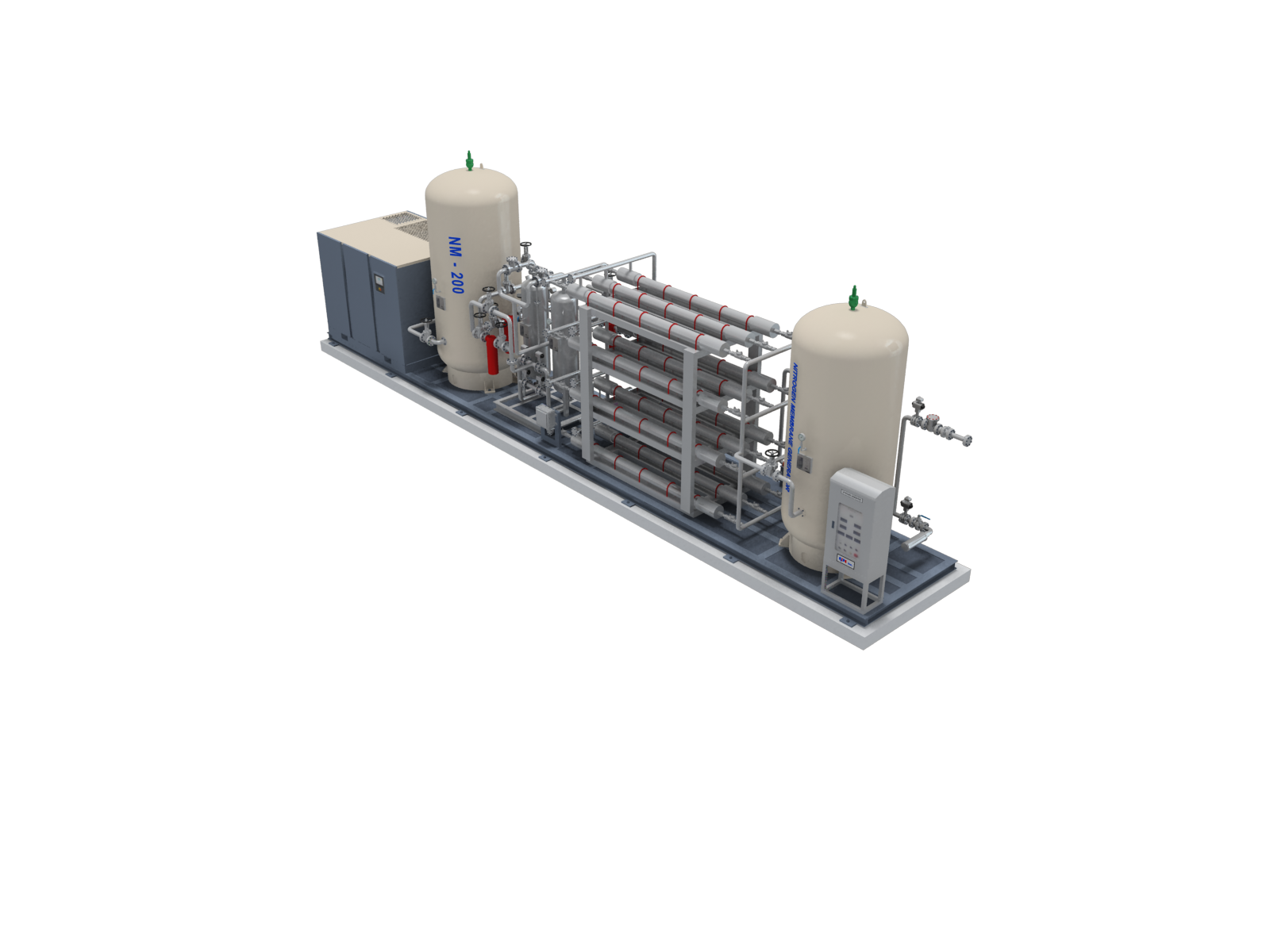

N2 PSA & Membrane Package

N2 PSA Package N2 PSA Generator utilizes the properties of CMS(Carbon Molecular Sieve) to separate nitrogen in air. CMS has the adsorption pore which adsorbs oxygen faster & more than nitrogen from the air. The whole process of nitrogen generator consists of Pressurization, Production, Equilibrium of pressure, Cleaning and Purge.

RIPE Inc.

N2 Membrane Package The Oxygen gas with the high permeability speed permeates out first through vent port. Nitrogen gas with the low permeability speed comes out later through the end of hollow fiber, when the compressed air passes through the membrane. The principle is to make use of the difference of the permeability speed of gas.

Application

Injection molding

Purge

Laser cutting

Fire extinguisher

Packing

Heat treatment

Soldering

Reflow

Photo Lab and Electronics

Product Application

Air Compressor

Air compressor is the equipment to produce compressed air.

Compressed air is used for separating nitrogen from air.

In the process of compression, moisture and heat happen.

To remove them, built-in or independent air dryer and after-cooler are necessary.

Filter

Filter is used for removing dust, particle and oil, etc. in compressed air.

Desiccant air dryer

This is used for removing moisture by using adsorbent.

It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration.

PSA Generator

In order to separate nitrogen from the compressed air, CMS(Carbon Molecular Sieve) is used as adsorbent.

PSA system consist of pressurization, production, purge, equilibrium of pressure and regeneration.

Nitrogen storage Tank

It is a buffer (storage) tank to supply the oxygen certain pressure, flow, purity.

LCP

LCP has control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced nitrogen.

Nitrogen supply

The purity of the produced nitrogen is up to 99.999%. Flow and pressure depend on customers needs.

LN2 Storage tank

It is the equipment for storing liquid nitrogen.

LN2 Vaporizer

It is the equipment for changing nitrogen from liquid into gas through vaporization.

Gas supply unit

In order to supply vaporized nitrogen with the certain pressure.

LCP

It controls the heater that is used when the vaporized nitrogen of certain temperature is required.

Air Compressor

Air compressor is the equipment to produce compressed air.

Compressed air is used for separating nitrogen from air.

In the process of compression, moisture and heat happen.

To remove them, built-in or independent air dryer and after-cooler are necessary.

Air Receiver Tank

Air receiver tank is the equipment to keep supplying the compressed air of certain pressure to the nitrogen generator stably.

It is also for the purpose of handling the load of compressor properly.

Filter

It is used for removing dust, particle and oil, etc. in compressed air.

Desiccant Air dryer

This is used for removing moisture by using adsorbent.

It consists of two adsorbers and it has the repeated cycles of adsorption and regeneration.

Membrane Generator

Membrane generator is to make use of the difference of the permeability speed of gas in order to separate gas.

Such oxygen and moisture with high permeability speed, permeate out first through vent port and then nitrogen gas with low permeability speed as marketable product comes out later through the end of hollow fiber when the compressed air pass through the membrane.

Nitrogen Storage Tank

It is a buffer (storage) tank to supply the oxygen certain pressure, flow, purity.

LCP(Local Control Panel)

LCP has control of the whole system into operation automatically or manually.

It also indicates purity, pressure and flow of the produced nitrogen.

Nitrogen Supply

The purity of the produced nitrogen is up to 99%. Flow and pressure depend on customer s needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese